Padel is absolutely exploding, and the demand for new courts is struggling to keep up. It's not just a sport; it's a social event, and that infectious energy is what's driving a massive global construction boom. Getting a court built right involves a lot of careful planning—from picking the perfect spot and laying the foundation to choosing the best turf and glass—to make sure it can handle the rush of new players.

Why Padel Court Construction Is Skyrocketing

Padel has quickly become more than just another racket sport. It's a genuine social phenomenon, and that’s what’s fueling this incredible surge in facility development across the globe. The core reason? It’s incredibly easy to pick up and immensely fun to play with friends, creating a level of demand that existing infrastructure just can't satisfy. For investors, sports clubs, and entrepreneurs, this gap is a golden opportunity.

What I've seen firsthand is that the sport’s magic lies in its accessibility. Tennis can take years to get good at, but with padel, total beginners are having rallies and laughing within their first hour on the court. This easy learning curve pulls in everyone—families, young professionals, active retirees—and is the engine behind its incredible grassroots growth.

Buy the best padel gear to level up your next game!

CHECK OUT this deal from Padel Market!Get ready to take your game to the next level with the latest padel gear from Padel Market! Fast EU and Worldwide Shipping

The Numbers Behind the Boom

The stats tell an undeniable story. Just last year, in 2023, the industry saw the construction of 5,816 new courts and the launch of over 2,500 new clubs worldwide. That's a massive 16% jump from the year before, pushing the total number of courts past 43,000. France was at the forefront of this wave, boasting an impressive 45% growth by adding 673 new courts, which really highlights the sport's momentum in Europe. You can dive deeper into these figures in the global padel construction trends report from Playtomic.

This isn't just about putting up walls and turf; it's about building community hubs. Successful padel clubs evolve into vibrant social centers, often featuring cafes, pro shops, and event spaces. This creates multiple streams of revenue that go far beyond just booking a court for an hour.

A Solid Investment Opportunity

For anyone managing a facility or looking for a smart investment, the math is incredibly appealing. Padel courts are compact. You can fit nearly three padel courts in the same footprint as a single tennis court, which means you can get a lot more revenue out of every square meter of land.

The combination of high player demand, efficient space usage, and strong community appeal makes padel court construction one of the most attractive ventures in the modern sports and leisure market.

Here are the key factors that make this such a compelling investment:

- High Occupancy Rates: From what I've seen, new courts are often booked solid from day one, which puts them on a fast track to profitability.

- Versatile Business Models: You aren't limited to one income stream. You can run pay-per-play models, offer memberships, host leagues and tournaments, or even book corporate events.

- Growing Market Recognition: As professional tours gain more media coverage, public interest just keeps climbing, bringing more and more people to the sport.

This upward trajectory shows no signs of slowing down. As more people discover how fun padel is, the need for high-quality, professionally built courts is only going to get more intense. If you've been thinking about getting into padel court construction, now is definitely the time.

Laying the Groundwork for Your Padel Project

Before a single shovel hits the dirt, the fate of your padel court project is sealed in the planning phase. Getting this right from the start is what separates a thriving club from a costly mistake. This is where you move from a great idea to a tangible plan, covering everything from the piece of land you choose to the very structure of the courts themselves.

The first real task is a rigorous site analysis. You can't just find a flat bit of land and assume it's good to go. You have to dig into local zoning laws and regulations. For example, trying to build a commercial padel club on a plot zoned for residential use is a non-starter without a variance—and that can be a long, expensive battle. Don't forget to check noise ordinances, either. The signature "pop" of a padel ball can become a major headache for nearby homes if you haven't planned for sound mitigation.

Accessibility is another huge piece of the puzzle. How easy is it for players to find and get to your location? Is there enough room for parking? Think beyond just the players; you need space for staff and, hopefully, spectators for future tournaments. I've seen too many projects where parking was an afterthought, and it becomes an immediate point of frustration for customers before they even swing a racket.

The Foundation is Everything

Once you've locked down a viable site, your attention has to shift to the ground beneath your feet. A solid, well-engineered foundation isn't just a recommendation; it's non-negotiable for a professional-grade padel court.

The industry standard, and for good reason, is a reinforced concrete slab. Trying to cut corners here is a classic rookie mistake that leads to a world of pain later on—think cracks, an uneven playing surface, and drainage nightmares that are incredibly expensive to fix.

A proper foundation for a padel court should be at least 15-20 centimeters (6-8 inches) thick. It absolutely must be reinforced with steel mesh (rebar) to handle the stress of constant play and seasonal weather changes. Drainage also has to be designed into the slab from the get-go. A tiny, almost imperceptible slope of around 1% is the secret sauce. It expertly guides rainwater away from the surface, preventing puddles and long-term moisture damage.

A flawed foundation will undermine every other component of your court. It doesn't matter how premium your turf or glass is; an unstable base guarantees premature wear, safety hazards, and a terrible playing experience. This is the one area where you absolutely cannot afford to be cheap.

Before you break ground, conducting a thorough feasibility study is a critical first step to make sure every part of your project is actually viable.

Indoor vs. Outdoor: A Practical Comparison

One of the biggest forks in the road you'll face early on is whether to build indoor courts, outdoor courts, or some kind of hybrid. This decision will have a massive impact on your construction budget, potential revenue, and day-to-day operations.

Let's break down the key differences:

Buy the best padel gear to level up your next game!

CHECK OUT this deal from Padel Market!Get ready to take your game to the next level with the latest padel gear from Padel Market! Fast EU and Worldwide Shipping

- Outdoor Courts: These are generally cheaper to build upfront because you're not constructing an entire building. The catch? Your business is completely at the mercy of the weather. A rainy season or a harsh winter can wipe out a significant chunk of your potential income.

- Indoor Courts: The initial investment here is substantially higher. You're building a structure that needs proper HVAC, insulation, and high-quality lighting. The huge advantage, though, is a year-round, weather-proof facility that can bring in steady revenue no matter what it's doing outside.

- Covered Courts: This is a great middle-ground option. Adding a permanent roof or canopy over outdoor courts protects players from rain and the harshest sun, which can significantly extend playing hours without the full expense of an enclosed building.

The global padel boom is proof that this level of planning pays off. Europe is a perfect example, with mature markets like Spain adding 1,300 courts and Italy adding a staggering 1,800 courts between 2022 and 2023 alone. What's even more telling is the explosive growth in newer markets—the UK doubled its court count, and Germany saw a 92% increase in the same period. This incredible demand is for well-built, well-planned facilities.

Ultimately, your choice between indoor and outdoor will come down to your local climate, your target audience, and your overall business model. For a deeper dive, check out our guide on choosing the right padel court for your project. Taking the time to weigh these options carefully will set your entire venture up for success.

Selecting Your Court Structure and Surface

When it comes to building a padel court, the materials you choose are far more than just line items on a budget. They fundamentally define how the game is played. Every shot, every sprint, every spin of the ball is a direct result of the interaction between the player, the ball, and the surfaces you’ve installed. Getting this right is non-negotiable.

You'll be making two huge decisions at this stage: the type of artificial turf and the specs for your structural frame and glass walls. These elements are a team; they have to work together to deliver on performance, safety, and longevity. Going cheap on the turf might feel like a win upfront, but you'll pay for it later in poor playability and rapid wear. Likewise, skimping on glass thickness isn't just a bad idea—it's a safety hazard.

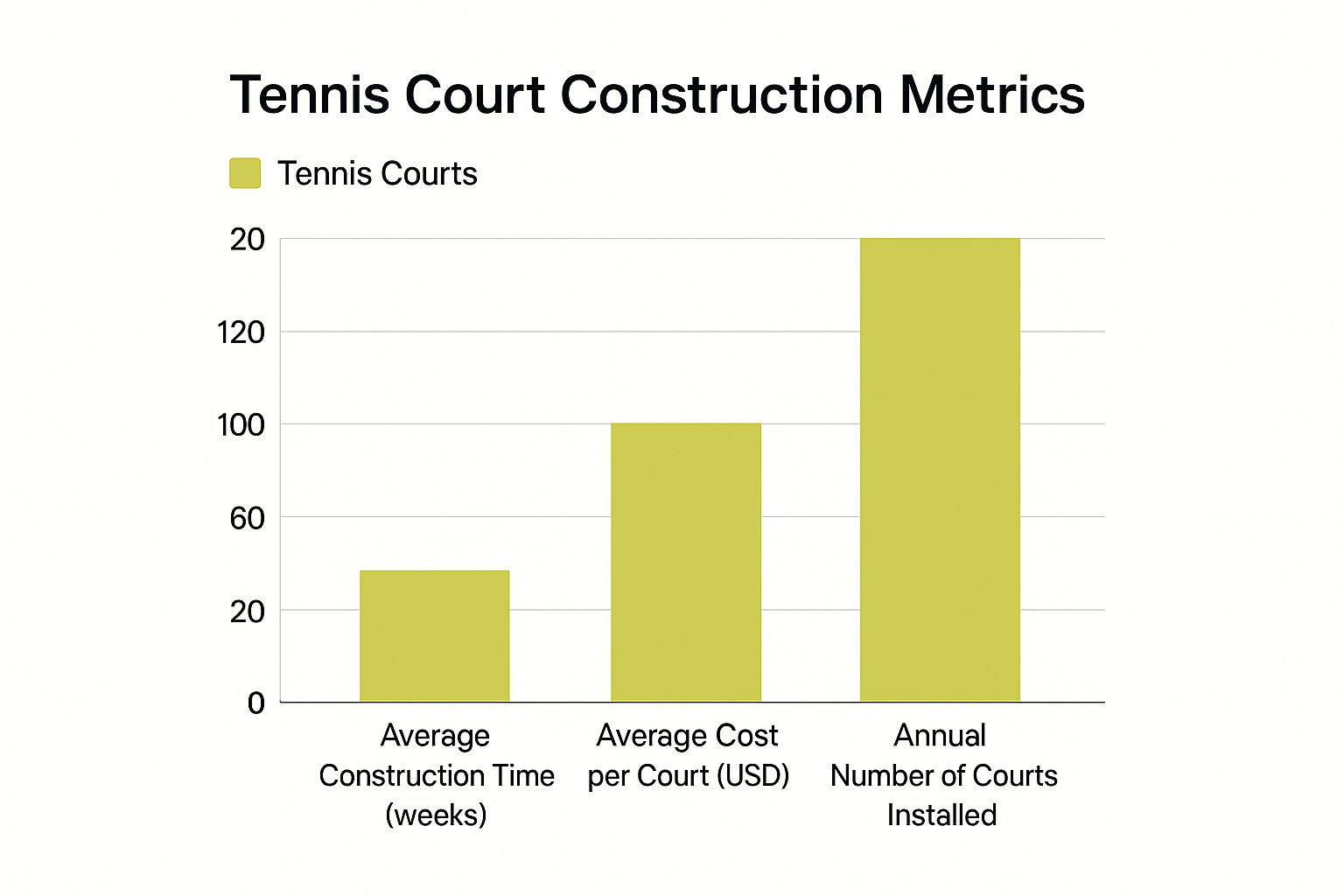

This infographic gives you a snapshot of key industry metrics, connecting the dots between construction timelines, typical costs, and the explosion in annual court installations.

As you can see, the sheer volume of new courts going up is pushing developers to make smarter, more informed choices about materials right from the start.

Choosing the Right Artificial Turf

The playing surface is the heart and soul of your court. From a distance, it might all just look like green carpet, but the specific type of artificial turf you lay down has a massive impact on everything—ball speed, bounce consistency, and even player comfort and grip.

You’ll generally encounter three main types of turf:

- Monofilament Turf: Most people consider this the gold standard for serious, competitive play. The fibers stand up individually, which lets the sand infill settle down deep and evenly. The result? A faster, more consistent game where players can pivot and turn with confidence. It's the go-to for clubs that host tournaments or competitive leagues.

- Fibrillated Turf: This turf has wider fibers designed to split over time, creating a dense, interwoven surface. It does an incredible job of holding the sand in place, making it a workhorse for high-traffic courts. The trade-off is that the game can feel a bit slower, and keeping the sand perfectly uniform can be a challenge.

- Textured (or Curled) Monofilament: This is a newer, smarter option. The fibers are curled to almost encapsulate the sand, stopping it from migrating all over the court. This is a game-changer for maintenance, as the sand stays put and provides a beautifully consistent surface. It's a fantastic choice if you want to minimize upkeep without sacrificing quality.

Expert Insight: Your turf choice should mirror your facility's purpose. Building a high-performance club for serious players? Monofilament is your best bet. Running a busy pay-and-play facility where durability is king? Fibrillated or textured turf will likely serve you better in the long run.

The Structural Frame and Tempered Glass

The enclosure is what makes padel, well, padel. You have the steel frame acting as the skeleton and the tempered glass walls serving as an active part of the playing field. Both have to be specified correctly for the court to be safe and perform as expected.

The frame, usually made from galvanized steel, must be strong enough to handle constant ball impacts and support the heavy glass panels without so much as a wobble. The thickness and quality of that steel are what will determine its lifespan, especially if the court is outdoors, battling the elements year-round.

When it comes to the glass itself, 10mm and 12mm tempered panels are the industry standards.

- 10mm Glass: This is a perfectly fine and common choice for private courts or smaller clubs. It meets all the safety standards and gives you a good rebound for recreational play.

- 12mm Glass: If you're building a commercial facility or plan on hosting tournaments, this is what you want. The thicker glass offers superior structural integrity, a much more solid and predictable rebound, and an extra layer of durability that easily justifies the higher price tag in a busy setting.

If you're thinking bigger and planning an enclosed facility, the structural demands go up another level. You can learn more about the unique challenges and advantages of building permanent indoor padel courts.

Choosing your court's surface and glass is a balancing act. You're constantly weighing performance against budget and durability against how much foot traffic you expect. By understanding the practical differences between these materials from the outset, you can build a court that not only meets player expectations but truly exceeds them.

Padel Court Surface and Glass Comparison

To make these decisions a bit clearer, here’s a breakdown of the most common options. This table compares the key components, helping you see how performance, maintenance, and cost stack up against each other.

| Component | Type | Best For | Maintenance Level | Typical Lifespan | Relative Cost |

|---|---|---|---|---|---|

| Artificial Turf | Monofilament | Competitive clubs, fast-paced play | Medium-High (regular sand top-up) | 5-7 years | High |

| Artificial Turf | Fibrillated | High-traffic public facilities, schools | Medium (sand can clump) | 7-9 years | Medium |

| Artificial Turf | Textured | Low-maintenance clubs, private courts | Low (sand stays in place) | 6-8 years | High |

| Glass Walls | 10mm Tempered | Private use, small clubs | Low (regular cleaning) | 15+ years | Medium |

| Glass Walls | 12mm Tempered | Commercial clubs, professional venues | Low (regular cleaning) | 20+ years | High |

Ultimately, investing in the right materials from day one ensures your court is not only a fantastic place to play but also a durable, long-term asset.

Getting a Handle on Your Project Budget and Timeline

Even the most brilliant court design and premium materials won't matter if your project goes off the financial rails or blows past its deadline. The true measure of a successful padel courts construction project comes down to disciplined budget management and a realistic, well-managed timeline. This is where the spreadsheets and calendars become every bit as crucial as the blueprints.

It's a common trap for first-time builders to focus only on the court itself—the turf, the glass, the frame. But the real costs are often hiding in the details. These "soft costs" can easily inflate your total expenditure by 20-30% or more if you haven't planned for them from the get-go.

Getting this right from the start means having solid systems in place for tracking jobs and costs efficiently. Every dollar and every day needs to be accounted for to keep your project moving toward the finish line.

Deconstructing the Real Costs

A ballpark figure isn't a budget; it's a guess. A genuine budget is itemized, breaking down every anticipated expense. This detailed approach is your best defense against nasty surprises and allows you to make smart, informed decisions when you inevitably need to adjust your spending.

A truly comprehensive budget must account for:

- Site Preparation: This is everything that happens before the foundation goes in. Think excavation, grading, soil testing, and installing proper drainage. If your site isn't perfectly level or has poor soil, these costs can climb quickly.

- Foundation Work: The reinforced concrete slab is a major line item. This includes the cost of the concrete itself, rebar, labor, and any necessary formwork.

- Court Materials: This is the price of the court "kit"—the steel structure, tempered glass panels, artificial turf, nets, and posts.

- Labor and Installation: Don't ever underestimate this one. You're paying for a skilled crew to assemble the structure, lay the turf, and carefully install the glass. This is absolutely not a DIY job.

- Permits and Fees: Your local municipality will have its own schedule of fees for building permits, inspections, and zoning approvals. These can add thousands to your project before a single shovel hits the ground.

- Contingency Fund: Think of this as your project's insurance policy. A contingency of 10-15% of the total project cost is a wise move to cover the unknowns, like hitting unexpected rock during excavation or dealing with supply chain delays.

A rookie mistake is seeing a quote for the court structure and thinking that's the all-in price. In reality, the groundwork, labor, and permits often make up a huge chunk of the total investment.

Creating a Realistic Project Timeline

Your timeline is your project's roadmap. A clear, well-structured schedule ensures everyone—from the excavation crew to the electricians—is on the same page and working efficiently. The trick is to break the entire project down into distinct phases with clear milestones and dependencies.

For example, you can't even think about erecting the court's frame until the concrete foundation has been poured and has had enough time to cure. Depending on the weather and concrete mix, this curing process can take up to 28 days. Building that non-negotiable waiting period into your schedule from day one is critical to avoiding a domino effect of delays.

Here’s what a typical project timeline might look like:

- Phase 1: Pre-Construction (4-8 weeks): This is the homework phase. You'll finalize the design, secure financing, obtain all necessary permits, and lock in your contractor.

- Phase 2: Groundwork (1-3 weeks): Time to get dirty. This includes site clearing, excavation, grading, and pouring the concrete foundation. This phase is almost entirely at the mercy of the weather.

- Phase 3: Curing (3-4 weeks): A game of patience. The concrete slab must fully cure and gain its required strength before bearing any weight. It’s a passive but absolutely essential waiting period.

- Phase 4: Court Assembly (1-2 weeks): Now the fun begins. The steel frame goes up, glass panels are installed, and lighting poles are put in place.

- Phase 5: Finishing Touches (1 week): The final stretch involves laying the artificial turf, applying the sand infill, installing the nets, and completing a final site cleanup.

While this timeline provides a solid framework, always remember that external factors like weather, permit hold-ups, and material delivery schedules will have an impact. The smartest project managers always build some buffer time into each phase to absorb minor setbacks without derailing the entire project.

Installing the Final Touches for a Pro-Level Court

With the heavy lifting done and the main structure in place, we get to the fun part—the details that make a court truly great. These finishing touches are what players see, feel, and remember. They’re the difference between a court that’s just okay and a facility that becomes the go-to spot in town.

First up, and arguably the most important, is the lighting. Nothing will kill the vibe of a new court faster than poor lighting. Bad lights create frustrating shadows, blinding glare, and inconsistent visibility, making evening games a nightmare. For a truly professional setup, LED lighting is the only way to go. It’s brighter, far more energy-efficient, and lasts ages compared to old-school metal halide systems.

Perfecting Court Illumination

The goal here is simple: you want uniform, shadow-free brightness across every inch of the playing surface. We measure this in LUX, which is just a unit for light intensity. The LUX level you need really depends on who will be using the court.

- Recreational and Club Play: For everyday use, training, and friendly matches, 200-300 LUX is the sweet spot. It’s plenty bright for clear visibility without feeling like you're under a stadium spotlight.

- Competitive and Tournament Play: When things get serious, you need to bump it up. Official competition standards usually call for 400-500 LUX so players and refs can track a fast-moving ball with ease.

- Televised Broadcasts: If you’re dreaming of hosting pro events with cameras rolling, the requirements jump significantly. You’ll be looking at 1000+ LUX to meet the demanding specs of broadcast cameras.

Where you put the lights matters just as much as how bright they are. Most setups use four to eight light poles around the perimeter of the court. The key is to angle them just right, so the light spreads evenly and you don't get any dark corners or annoying glare bouncing off the glass.

Applying the Sand Infill Correctly

Now that the artificial turf is rolled out, it’s time for the silica sand infill. This isn't just cosmetic; the sand is crucial for performance and player safety. It holds the turf fibers upright, helps create a consistent ball bounce, and gives players the right amount of grip to move and slide without risking injury.

This step needs to be done with care. You’re aiming to spread about 8-12 kg of sand per square meter, though you should always check the turf manufacturer's recommendation. The trick is to brush the sand in meticulously so it settles deep down between the grass fibers instead of just sitting on top. A sloppy job here leads to a patchy, unpredictable surface, which is a huge pet peeve for any regular player.

Here's a pro tip that often gets missed: use rounded silica sand, not sharp construction sand. The rounded grains won't cut or wear down the turf fibers, which will dramatically extend the life of your court.

Adding Essential Player Amenities

The last few pieces of the padel courts construction puzzle are all about the player experience. These are the thoughtful additions that show you’ve built a quality facility.

- Net System: Don't cheap out on the net. A high-quality, tensioned net is a must. It needs to be set to the official height—88 cm in the middle and 92 cm at the posts. A good winch system makes it easy to keep it perfectly taut.

- Player Benches: A simple bench just outside the court gives players a place to rest, stash their gear, and keep water bottles from cluttering the playing area.

- Accessible Gates: Make sure your entrance gates are wide enough for wheelchair access. This small detail makes your facility welcoming and inclusive for everyone.

This focus on quality is more important than ever, given the sport’s explosive growth. The global padel market is expanding at an incredible rate. One recent report noted that over 7,187 new courts were built in a single year, pushing the worldwide total past 50,000. The number of padel clubs jumped by 26% year-over-year, which works out to nearly nine new clubs opening every single day.

This trend shows no signs of slowing down. Projections estimate we'll see more than 81,000 courts worldwide by 2027, proving the demand for top-tier, professional facilities is only getting stronger. You can dive deeper into these padel court construction growth trends at Padel Business Magazine.

Maintaining Your Padel Court for Peak Performance

The final nail is hammered, the last grain of sand is brushed into place, and your court is officially ready for action. But the real work of a successful padel courts construction project is just beginning. It's best to think of your new court not as a finished product, but as a high-performance asset that needs consistent upkeep to deliver a great return on your investment.

Proactive maintenance is everything. It's the secret to longevity, player safety, and ultimately, building a great reputation. A court that’s clean, safe, and plays consistently is one that players will book time and time again. For true long-term value, adopting a strategy for comprehensive asset management for construction is a professional approach that always pays off.

Your Essential Maintenance Schedule

When it comes to court care, a solid routine is your best friend. Breaking down tasks into weekly, monthly, and even annual checks makes the entire process manageable and ensures nothing critical gets missed.

A simple maintenance schedule is the difference between a minor fix and a major, expensive repair down the road.

- Weekly Tasks: These are the non-negotiables, especially for a busy court. You'll want to regularly brush the artificial turf to keep the sand evenly distributed, clear away any leaves or debris, and give the glass panels a thorough cleaning. It keeps the court looking sharp and guarantees a predictable playing surface.

- Monthly Checks: Once a month, it's time for a deeper dive. Inspect the net to ensure proper tension—it should be 88 cm high right in the center. Give the entire steel structure and fencing a once-over, looking for any signs of rust or bolts that might have loosened. This is also the perfect time to check your sand levels and top up any sparse areas.

A well-maintained court is a safe court. These regular inspections are your first line of defense against injuries caused by wear and tear, letting players focus on their match without a second thought about the facility's condition.

Tackling Common Court Problems

Even with the best routine, you'll run into specific issues, often influenced by your local climate and how heavily the courts are used. Knowing how to handle them quickly is what sets a great facility apart.

In humid climates, for example, moss and algae can be a persistent problem, creating a slippery and dangerous surface. Periodically applying a specialized, turf-safe algaecide can stop this buildup before it even starts.

Another common headache is sand compaction, especially in high-traffic zones like the service boxes and near the net. A deep brushing or decompaction with a specialized machine aerates the sand, which immediately restores proper drainage and the court's natural bounce. And since regular play takes a toll on the players, too, sharing info on muscle recovery techniques for padel players can be a fantastic resource for your members.

By treating maintenance as a core part of your operations from day one, you’re actively protecting the significant investment you’ve made. This commitment to quality is what will keep your court a top destination for players for years to come.

Got Questions About Building Padel Courts? We've Got Answers

Even the most buttoned-up construction plan hits a snag or two. When you're building padel courts, a handful of questions pop up time and time again. Getting these sorted out early on will save you a world of trouble—not to mention time and money. Let's tackle some of the most common ones I hear from club owners and developers.

How Long Does It Really Take to Build a Padel Court?

Everyone wants to know the timeline. For a single outdoor court, you're realistically looking at a window of 8 to 12 weeks, from the first shovel in the ground to the first serve.

This isn't just one long stretch of work, though. It breaks down into distinct phases: planning and permitting can eat up 4-8 weeks before you even start. Then comes 1-3 weeks for groundwork, followed by the all-important 3-4 week wait for the concrete to cure properly. The final assembly and finishing touches usually take another 2-3 weeks.

Of course, that’s the "everything goes right" scenario. The biggest wildcard is always the weather. A few weeks of solid rain can bring your groundwork to a screeching halt. Don't forget potential delays with permit offices or material shipments, which can also throw a wrench in the schedule.

What Is the Standard Size of a Padel Court?

The playing area itself is a strict 10 meters wide by 20 meters long. That part is non-negotiable for a regulation court.

But the actual space you need—the total footprint—is bigger. You have to factor in the steel structure and leave a bit of a buffer zone for safety and just getting around. As a solid rule of thumb, plan for a total area of at least 11 meters by 21 meters for one court.

When you're laying out multiple courts, don't cram them together. My advice is to leave at least one full meter between each court. It's crucial for player safety and gives your maintenance crew room to work. It just looks more professional, too.

Can I Install a Padel Court on an Existing Tennis Court?

Absolutely. In fact, this is one of the smartest and most cost-effective ways to bring padel to your club. A standard tennis court (around 18m x 36m) is a massive piece of real estate. You can often fit two, sometimes even three, padel courts right on top of it.

The huge advantage here is that you can slash your groundwork costs because a stable, level base is already in place. But—and this is a big but—you have to inspect that old surface first. Any major cracks or a significant slope in the existing foundation need to be addressed before you even think about building on it.

How Much Maintenance Does a Padel Court Require?

Padel courts are pretty low-maintenance, which is great, but they aren't no-maintenance. A little bit of regular care goes a long way in protecting your investment and keeping players safe.

Here’s a simple maintenance schedule to follow:

- Every Week: Give the artificial turf a good brushing to keep the sand evenly distributed. A quick wipe-down of the glass panels keeps them looking sharp.

- Every Month: Check the net tension—it can sag over time. Also, do a quick walk-around and inspect the structure for any bolts or fittings that might have loosened up.

- Every Year: It's time for a deep clean of the turf and a top-up of the sand infill. This keeps the playing surface consistent and safe.

Staying on top of this stuff prevents minor issues like compacted sand or a bit of moss from turning into expensive, time-consuming repairs down the road.

At Padel Rumors, we're dedicated to helping you navigate every stage of your padel journey. From construction insights to finding the perfect gear, explore all our resources.